This post expands on (and updates) a few of my earlier posts about developing for the STM32F0 microcontroller. Some parts have become easier and I've found a few more useful ways to get things done. Some of the commands below assume a Debian-based Linux distribution, but should be reworkable for your particular setup.

Let's start by making some directories for the STM32 tools and projects:

$ mkdir ~/stm32

$ mkdir ~/stm32/projects

Installing the Toolchain

The GCC ARM Embedded package is a collection of utilities (compiler, assembler, libraries, debugger, etc.) that's maintained by ARM employees. It's available in the regular repositories, but you can use a PPA to get more up-to-date versions. OpenOCD facilitates communication between your PC and the ST-Link programmer. Install both tools:

$ sudo add-apt-repository ppa:terry.guo/gcc-arm-embedded

$ sudo apt-get update

$ sudo apt-get install gcc-arm-none-eabi libnewlib-arm-none-eabi libnewlib-doc gdb-arm-none-eabi openocd

There's currently a minor bug: those packages don't include the newlib-nano library. If you need newlib-nano you can manually install the GCC ARM Embedded package. Instead of using the above three commands, use these:

$ sudo apt-get install openocd ia32-libs

$ cd ~/stm32

$ wget https://launchpad.net/gcc-arm-embedded/4.8/4.8-2014-q1-update/+download/\

gcc-arm-none-eabi-4_8-2014q1-20140314-linux.tar.bz2

$ tar -xjvf gcc-arm-none-eabi-4_8-2014q1-20140314-linux.tar.bz2

$ echo export PATH=$PATH:/home/username/stm32/gcc-arm-none-eabi-4_8-2014q1/bin >> ~/.bashrc

$ source ~/.bashrc

Regardless of how you install GCC Arm Embedded, you'll also want the CMSIS and STM StdPeriph libraries:

$ cd ~/stm32

$ git clone https://github.com/szczys/stm32f0-discovery-basic-template.git

$ cd stm32f0-discovery-basic-template/Libraries/

$ make

We're now ready to build and flash some firmware. I'll cover three ways to accomplish that: using the command line, using the Geany IDE, and using the Eclipse IDE.

Building and Flashing: From the Command Line

For a very simple workflow you can just use the command line to get everything done. Write your code in whatever editor you like, and use a Makefile to encapsulate all of the build, debugging and device programming commands.

My basic empty project is available as a zip file or through my stm32f0-empty-project repository on GitHub. Extract it to ~/stm32/projects/. It has a main() that just configures a GPIO and toggles it in an infinite loop. The f0lib/ directory contains my incomplete and unpolished collection of potentially reusable code. There's also a Makefile and configuration files for GDB and OpenOCD. Usage is trivial:

make compiles the firmware into an ELF and a BIN.

make install flashes the firmware to the STM32F0 with OpenOCD.

make clean deletes the ELF and BIN.

make debug_server, make debug_nemiver and make debug_cli are used for debugging. More on this in the debug sections below.

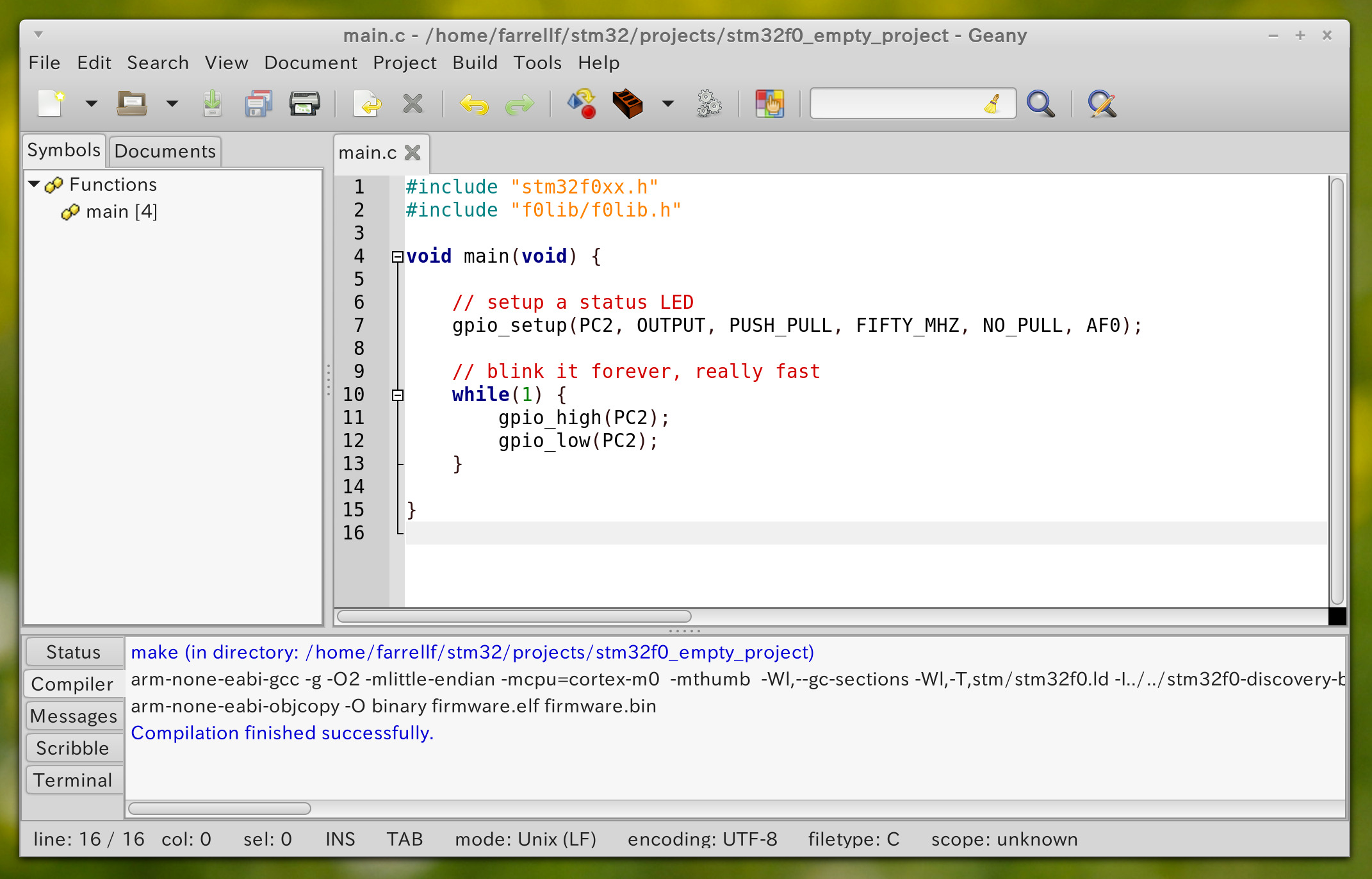

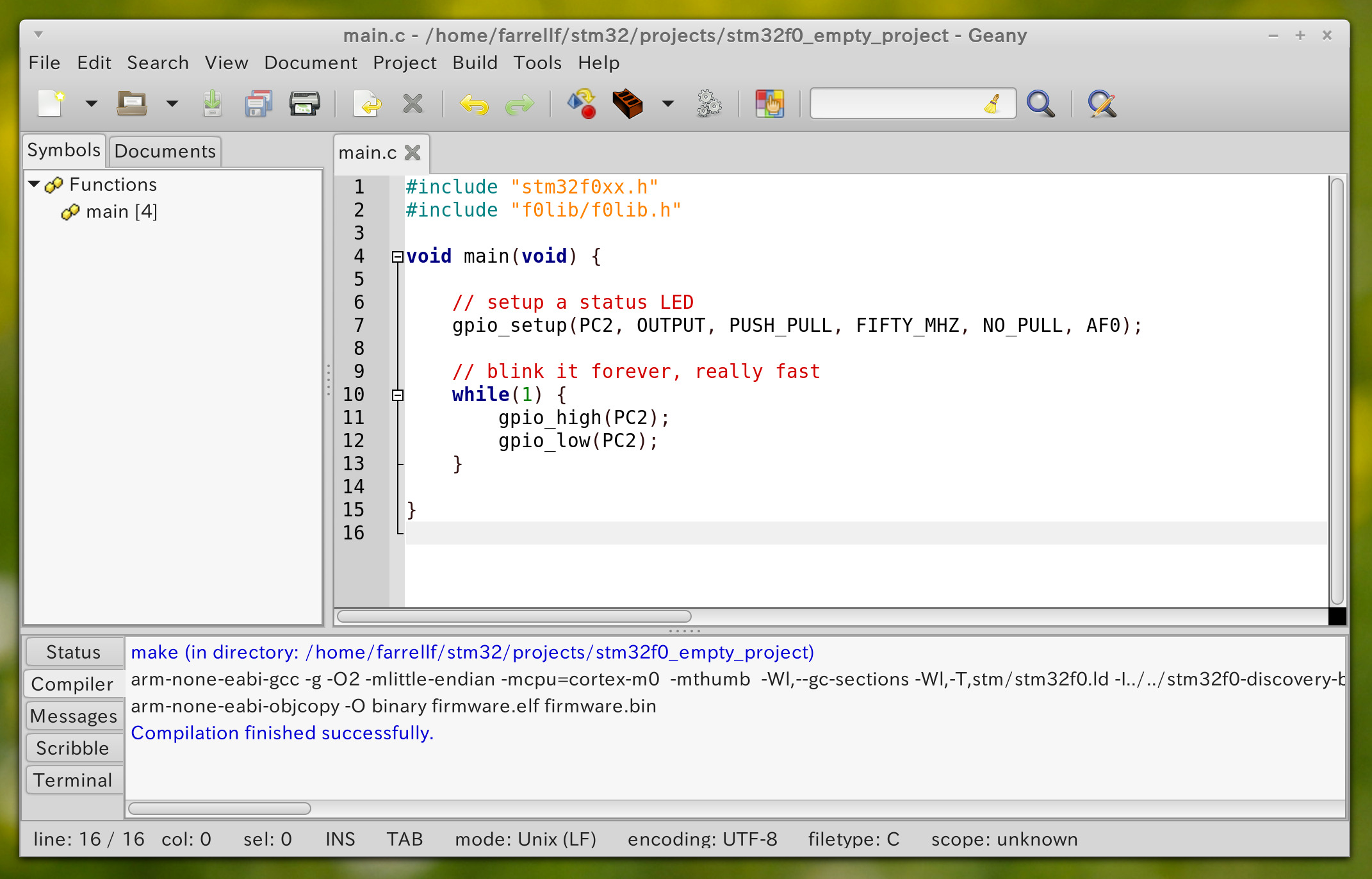

Building and Flashing: With the Geany IDE

Geany is a simple IDE and perhaps my favorite environment for programming in C. The IDE is essentially a text editor with a few extra features to support coding. It's minimalist and very fast. The only settings you need to change are the build commands. Go to Build > Set Build Commands. Configure them as compile = make clean, build = make, execute = make install. While this might sound weird, it makes the three build icons in the toolbar perfect for one-click actions instead of having to use the drop-down build menu.

Side note: if you're using Cinnamon or Gnome3 with a high-DPI display, the experimental GTK3 support in Geany gives you a beautiful high-DPI-friendly IDE. You'll have to build Geany from source with ./configure --enable-gtk3 && make && make install.

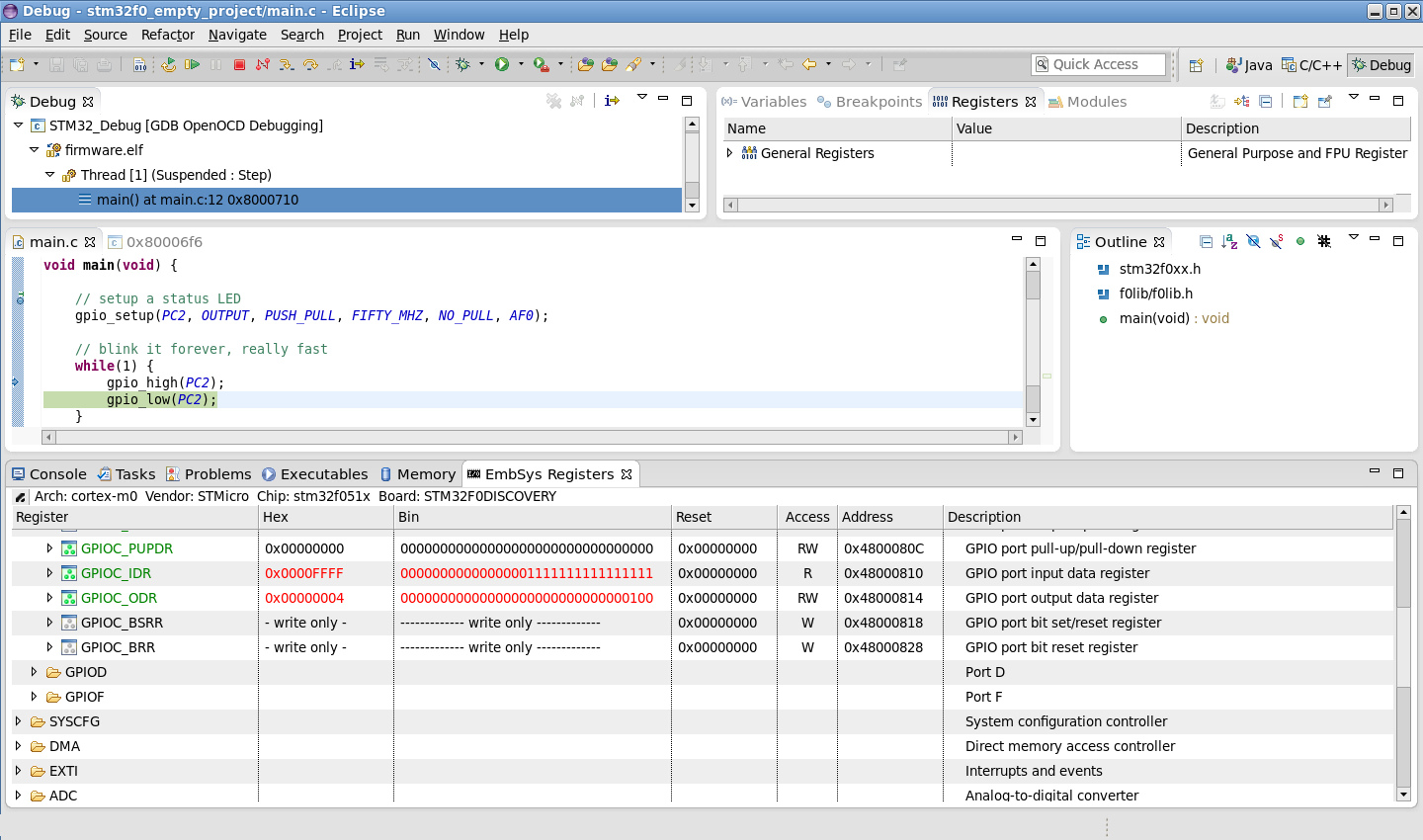

Building: With the Eclipse IDE

Many people prefer the Eclipse IDE. While I don't care for it's busy interface and relatively sluggish performance, there is a must-have plug-in that gives awesome annotated register views in the debugger. Start by installing the Eclipse and CDT packages, then install the GNU ARM Eclipse and EmbSysRegView plug-ins. Don't install Eclipse from the repositories -- the repo version of Eclipse is a few years old.

Download from https://www.eclipse.org/downloads/

Extract to ~/stm32

Open Eclipse

Help > Install New Software > Work with > Kepler

Programming Languages > C/C++ Development Tools

Help > Install New Software > Add

Name = GNU ARM Eclipse Plug-in

Location = http://gnuarmeclipse.sourceforge.net/updates

Select: Cross Compiler Support, Generic Project Templates, STM32Fx Project Templates, OpenOCD Debugging Support

Help > Install New Software > Add

Name = EmbSysRegView Plug-in

Location = http://embsysregview.sourceforge.net/update

Select: embsysregview (both components)

I only use Eclipse for debugging, so you might be better served by reading the GNU ARM Eclipse plug-in documentation. My way is a bit of a dirty hack to just get things working well enough to debug. Here's what I do:

File > New > C Project

Executable > Empty Project > Cross ARM GCC > Next > Next

Toolchain Path = ~/stm32/gcc-arm-none-eabi-4_8-2014q1/bin

Finish

Copy the contents of your project folder into the Eclipse project's folder. Then in Eclipse:

Right click on project > Refresh

Right click on project > Properties

C/C++ General > Paths and Symbols > GNU C > Add > File system

Navigate to: ~/stm32/stm32f0-discovery-basic-template/Libraries/CMSIS/Device/ST/STM32F0xx/Include

OK > OK > Yes

Right click on project > Properties

C/C++ Build > Build Settings tab

Uncheck “Use default build command”

Uncheck “Generate Makefile automatically”

Build command = make

Build directory = ${workspace_loc:/your_project_name_goes_here}

C/C++ Build > Behavior tab

"Build (incremental build)" = leave it empty

Again: I only use Eclipse for debugging. If you actually want to do any development in Eclipse, don't do what I do.

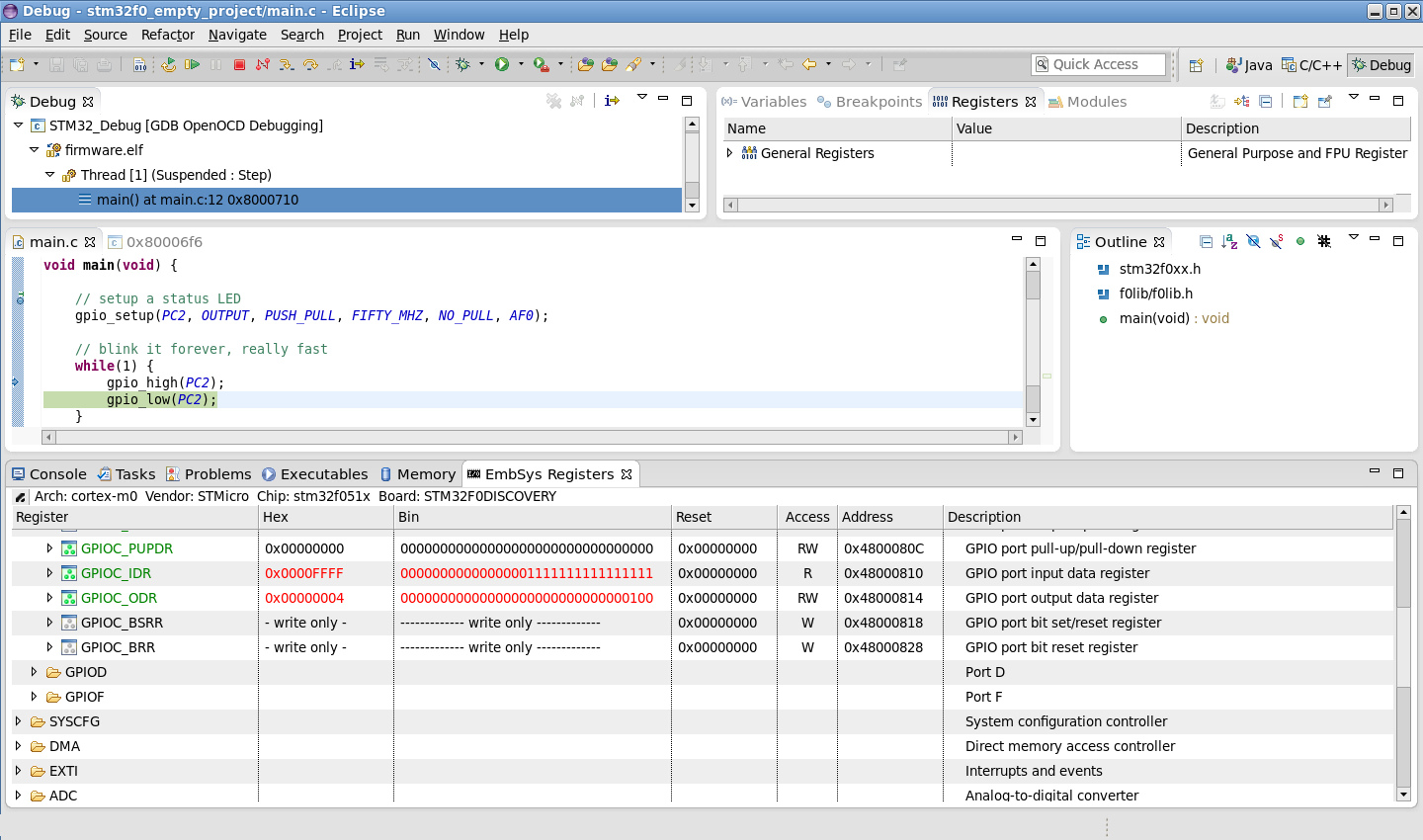

Debugging: With the Eclipse IDE

Having already prepared your project, now setup the debugging parts:

Right click on project > Debug as > Debug Configurations

Double-click on GDB OpenOCD Debugging

Name = STM32_Debug

Debugger tab

Uncheck “Start OpenOCD locally”

GDB Client Setup Executable = arm-none-eabi-gdb

Apply

Close

Window > Preferences

C/C++ > Debug > EmbSys Register View

Architecture = cortex=m0

Vendor = Stmicro

Chip = stm32f051x

Board = STM32F0DISCOVERY

In a terminal in the project directory: make debug_server

(Leave this running)

Click on the debug drop-down in the toolbar > STM32_Debug > Yes

Window > Show View > Other

Debug > EmbSys Registers

You can now debug using step/next/etc. Double-click on registers in the EmbSys Registers tab to view their contents. It automatically updates as you step though code.

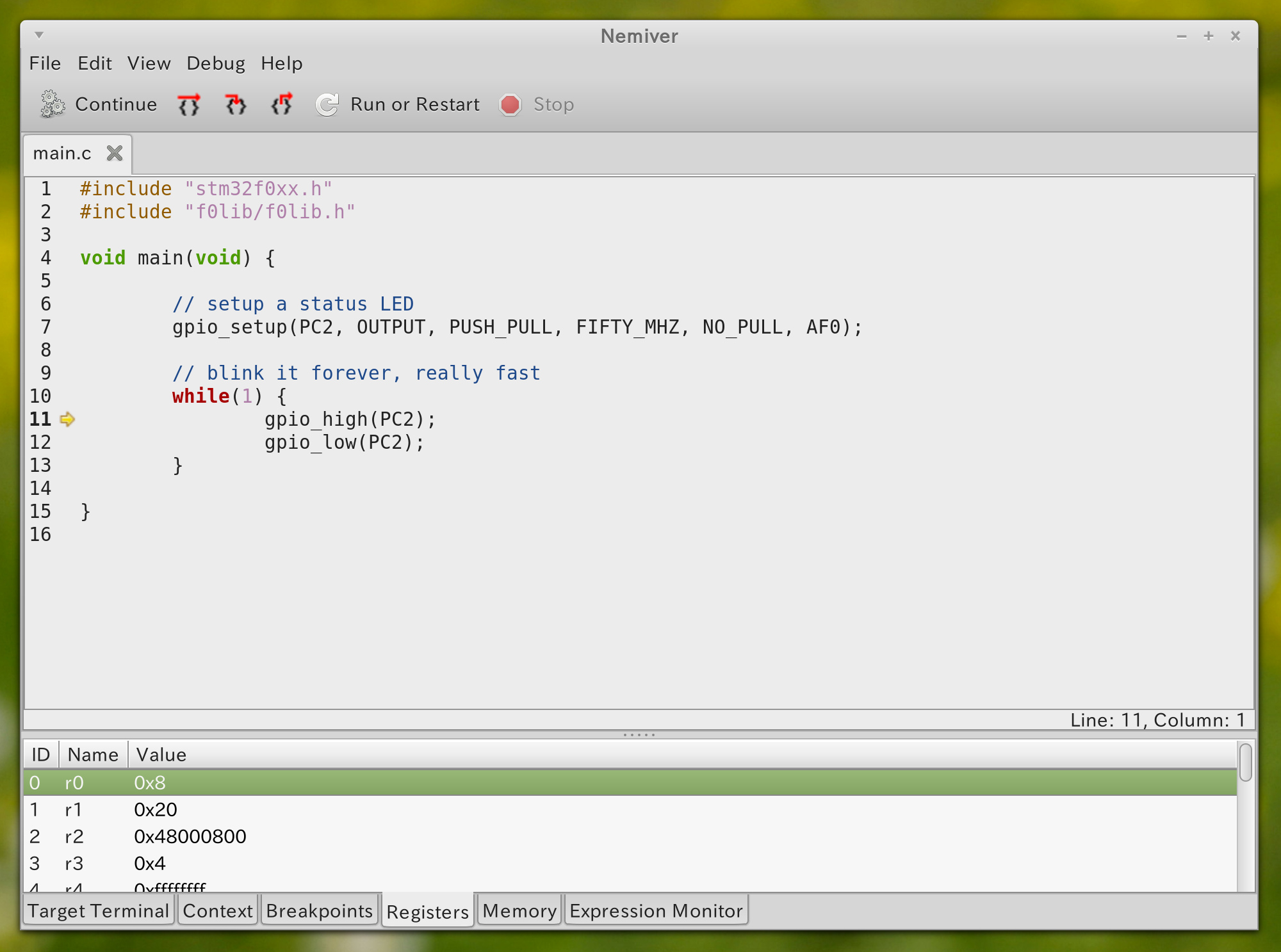

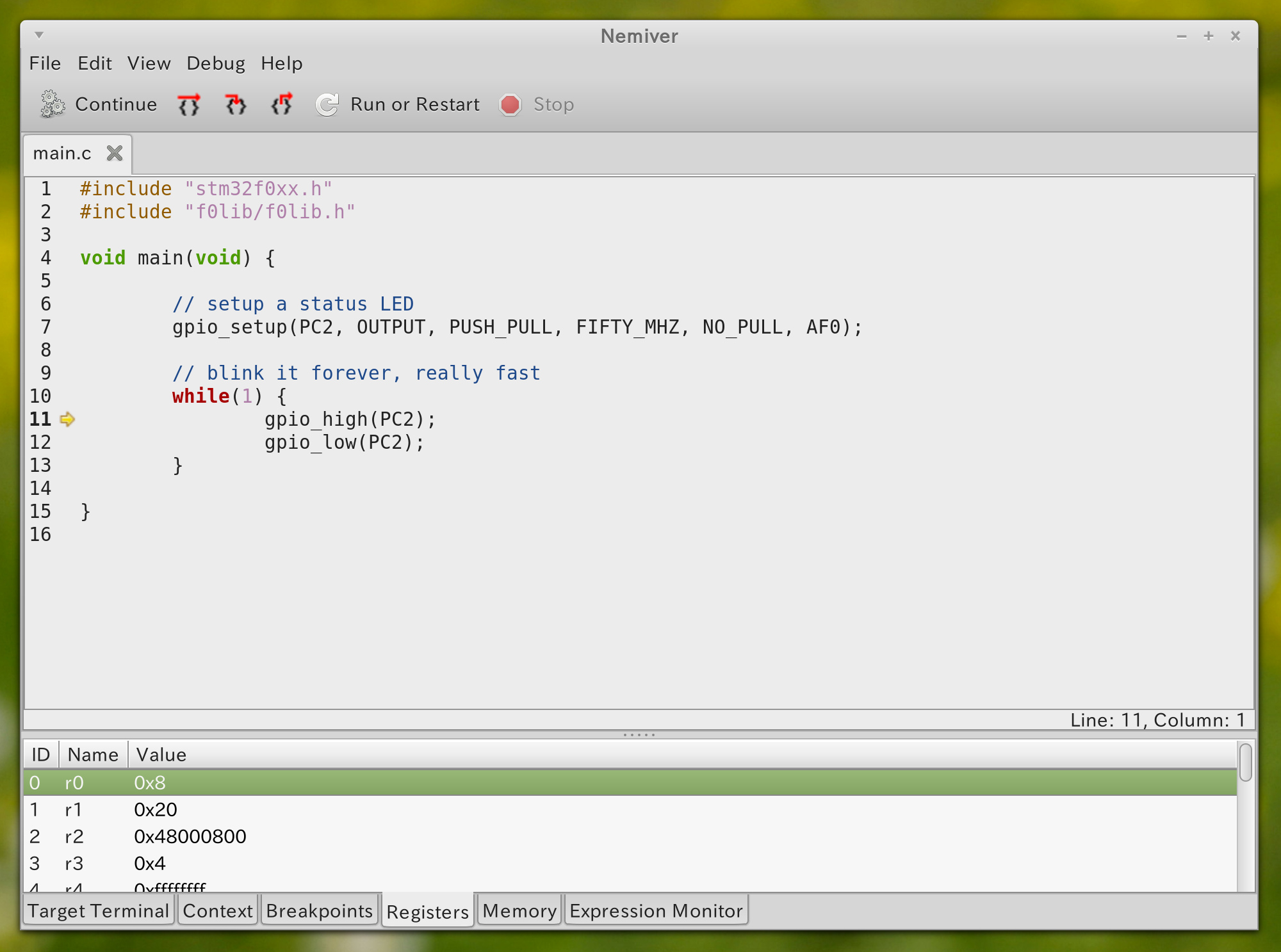

Debugging: With Nemiver

Nemiver is a fast and no-frills debugger. Using it with this project is trivial:

$ make debug_server

$ make debug_nemiver

make debug_server will have to stay running for the duration of the debugging process, so run it in a separate terminal window. After closing Nemiver you can close the server with Ctrl-C.

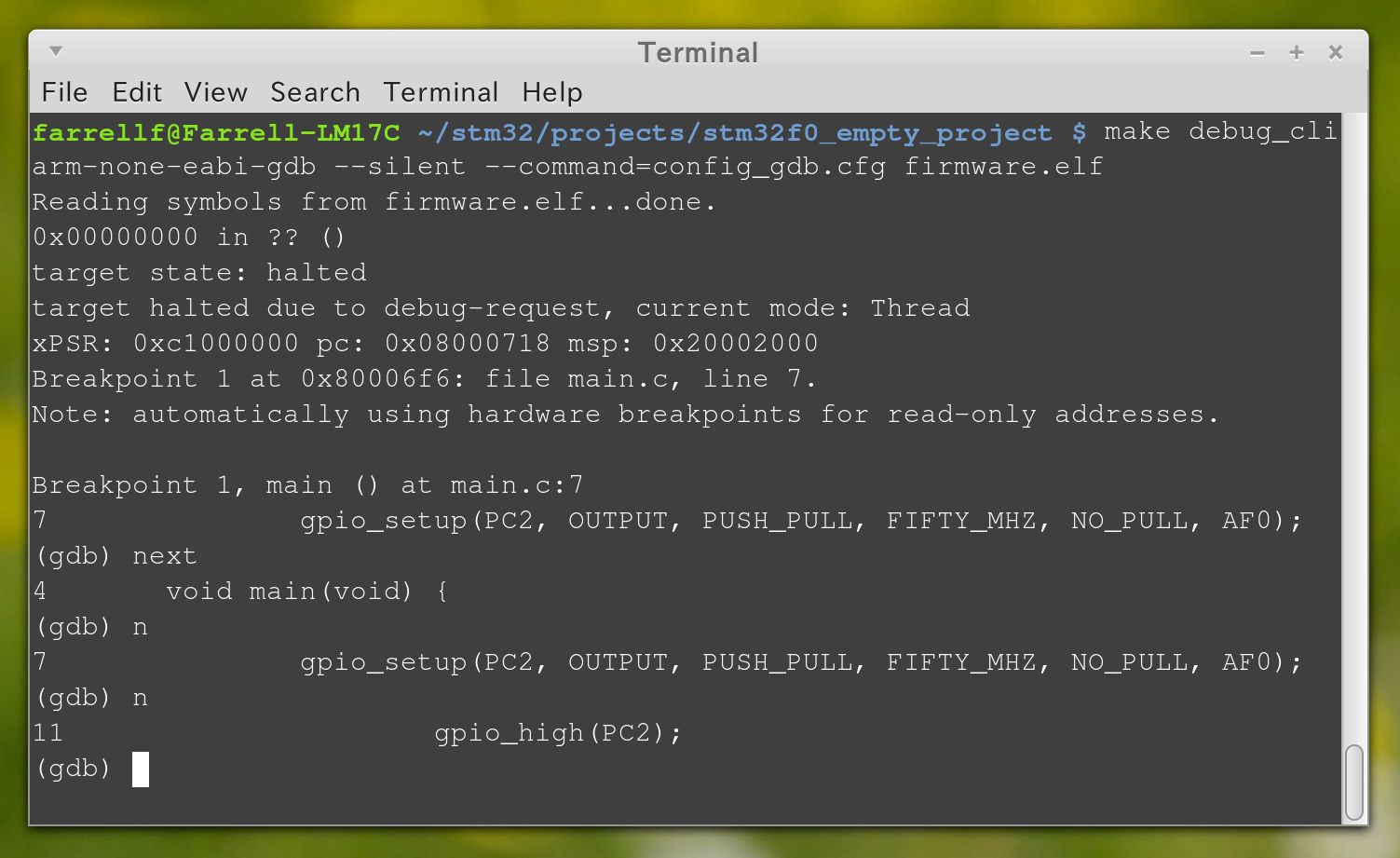

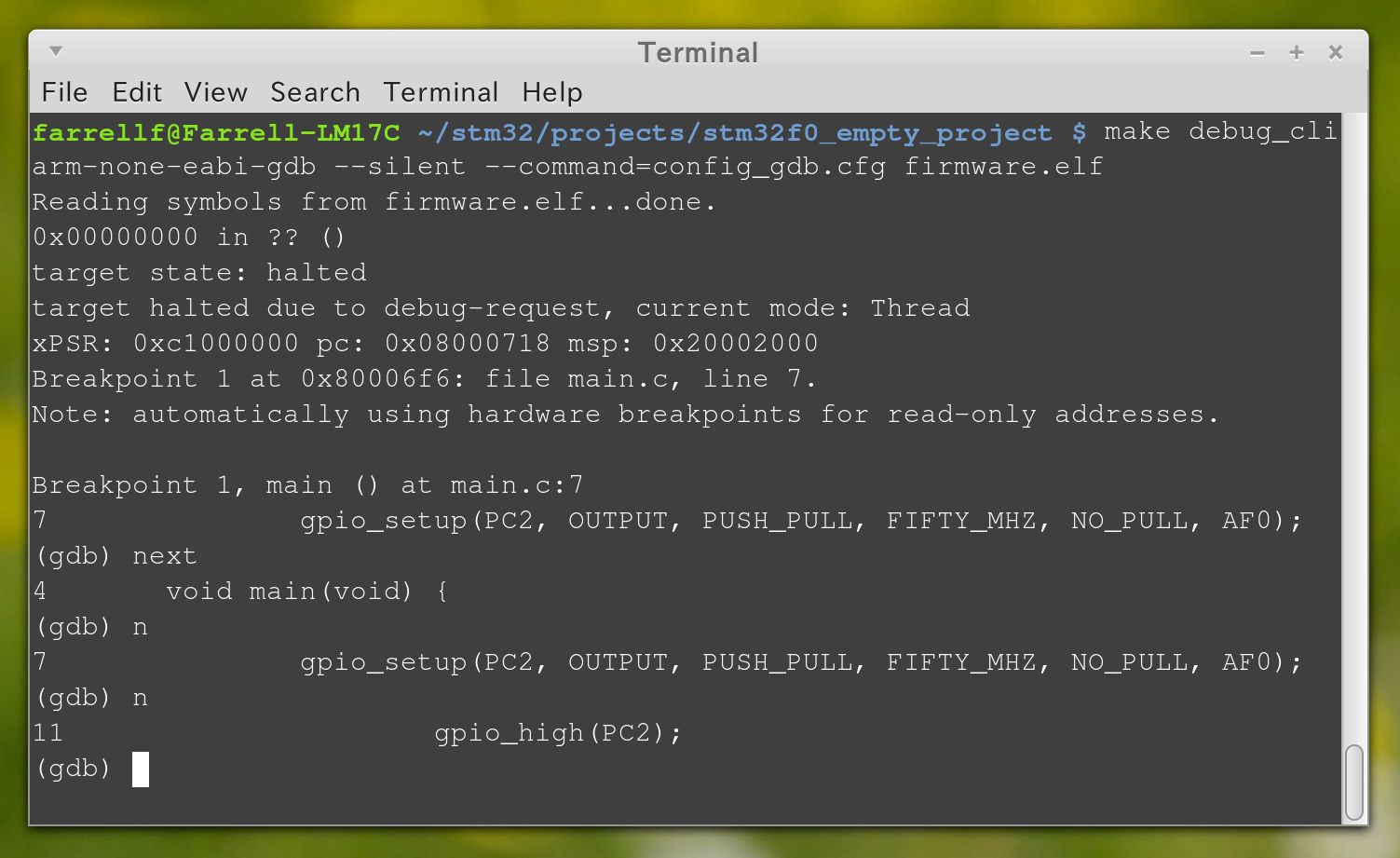

Debugging: From the Command Line

Command line debugging with this project is also really easy:

$ make debug_server

$ make debug_cli

make debug_server will have to stay running for the duration of the debugging process, so run it in a separate terminal window. After closing gdb you can close the server with Ctrl-C.